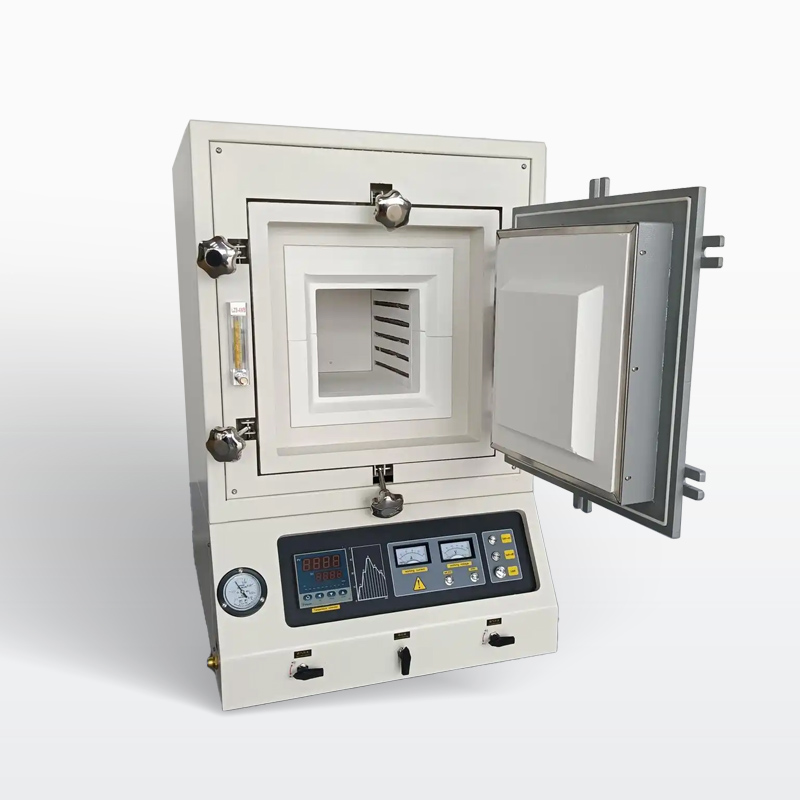

Controlled Atmosphere Furnace

- Model: CAF

- Power Supply: 380V 3Ph 50Hz (Customizable)

- Application: Heat treatment

- Working Temperature: 1200°C to 1800°C

- Control Accuracy: ± 1°C

- Heating: Electric heating

- Heating Control: SSR or SCR power controllers

- Temperature Control: Meter or PLC control

- Color: Customizable

Controlled atmosphere furnace is a device used for heating and processing materials in a specific atmosphere environment. It can provide an oxygen-free or low-oxygen atmosphere and is suitable for various heat treatment, sintering, annealing, quenching and other processes of different materials.

Atmosphere furnaces play a significant role in various fields such as scientific research and industrial production. They help improve product quality and performance, as well as promote the research and development of materials science.

▶ FEATURES

- Compact structure: The shape is usually box-like, occupying relatively less space and being easy to install in laboratories or production workshops.

- Varied atmospheres: Various protective or reactive gases such as nitrogen, hydrogen, and carbon monoxide can be introduced to meet different process requirements.

- Uniform temperature: Through reasonable layout of heating elements and design of gas flow inside the furnace, good temperature uniformity can be achieved.

- Widely applicable: Suitable for thermal treatment processes such as sintering, annealing, quenching, and tempering of materials, as well as the preparation and processing of ceramics, powder metallurgy, electronic components, etc.

- Convenient operation: Generally equipped with an intuitive control panel, facilitating the setting and monitoring of temperature, atmosphere, etc.

- Safety: Features multiple safety protection designs, such as overheat protection and gas leakage detection.

- Energy-saving performance: Utilizes high-performance insulation materials and insulation design, with low surface temperature, achieving significant energy-saving effects.

- Precise temperature control: High-precision temperature control system ensures the accuracy of the heat treatment process.

- Uniform heating: Optimized furnace design ensures uniform heating of materials.

1