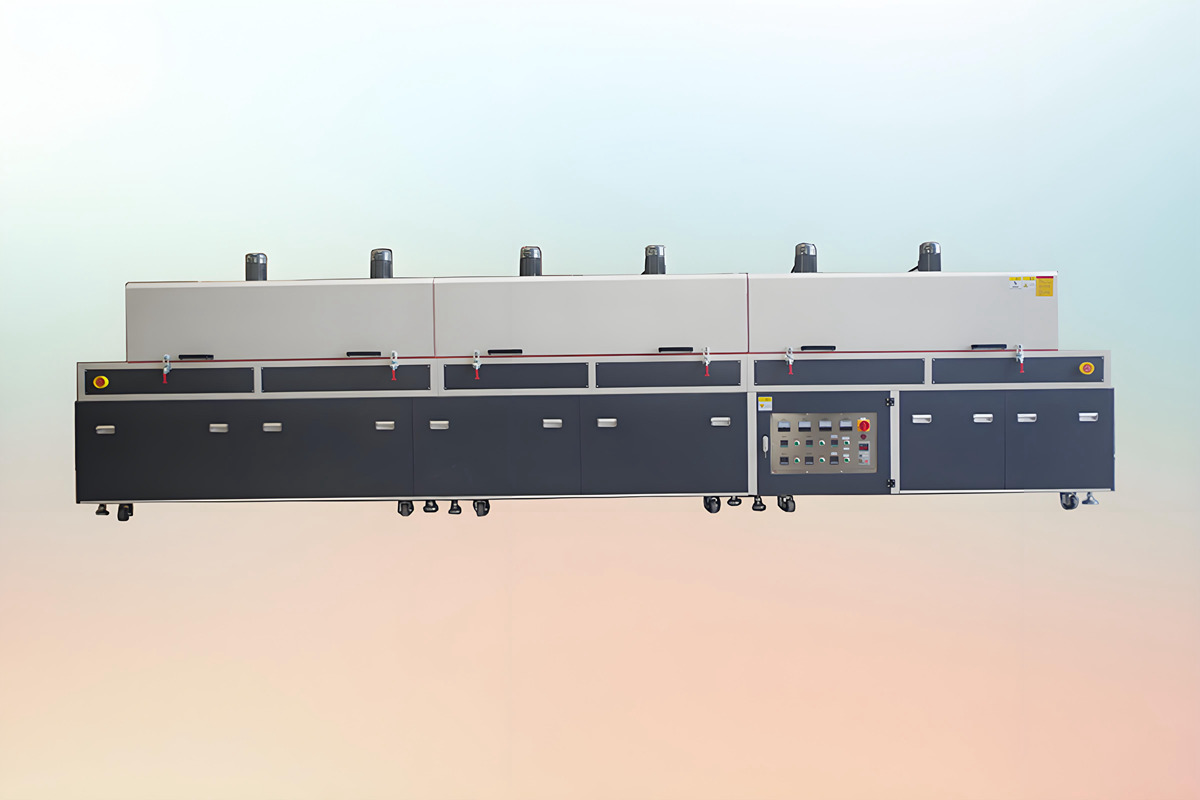

The copper busbar heat shrinkage Oven

- Model: DHF

- Power Supply: 380V 3Ph 50Hz (Customizable)

- Application: Powder drying

- Working Temperature: RT+30°C to 200°C

- Control Accuracy: ± 1°C

- Heating: Electric heating

- Heating Control: SSR or SCR power controllers

- Temperature Control: Meter or PLC control

- Color: Customizable

Tunnel oven is a continuous industrial baking system designed for high-volume production. It features a elongated chamber divided into multiple temperature-controlled zones, allowing precise regulation of heat, airflow, and humidity during the baking process. Products are transported through these zones on a conveyor belt, ensuring uniform baking and optimal efficiency.

▶ APPLICATIONS

- The copper busbar heat shrinkage

▶ FEATURES

- Durable tubular heating elements

- All welded construction

- Durable recirculating blower

- Adjustable exhaust outlet damper

- Durable belt

- Insulated with alumina silicate fibre insulation

- 304 stainless steel interior and painted exterior

▶ AIRFLOW PATTERNS

- Comnination (horizontal & vertical up) air flow

▶ CONTROL

- Digital temperature controller

- SSR or SCR power controllers

- Heat ON/OFF switch

- High volume recirculation blower

- Timer with range up to 0 to 999 hours/minutes/seconds

- Audible and visible alarm indicators

- Control Accuracy: ±1°C

- Uniformity: ±5°C

- Available input power supply to your specifications

- Temperature recorder (optional)

- PLC with HMI(touch panel) (optional)

- Programmable temperature controllers (optional)

▶ SAFETY PROTECTION

- Separate excess temperature interlock to turn off heat on malfunction of main temperature controller

- Electrical interlock shuts off heat if recirculating blower is broken

1